Long-Standing History. Long-Lasting Solutions

OUR GOAL

Create Excellent Products and Partnerships

Fabricated Heat Treating Work Carriers

High-temperature work carriers built to withstand repeated thermal cycling.

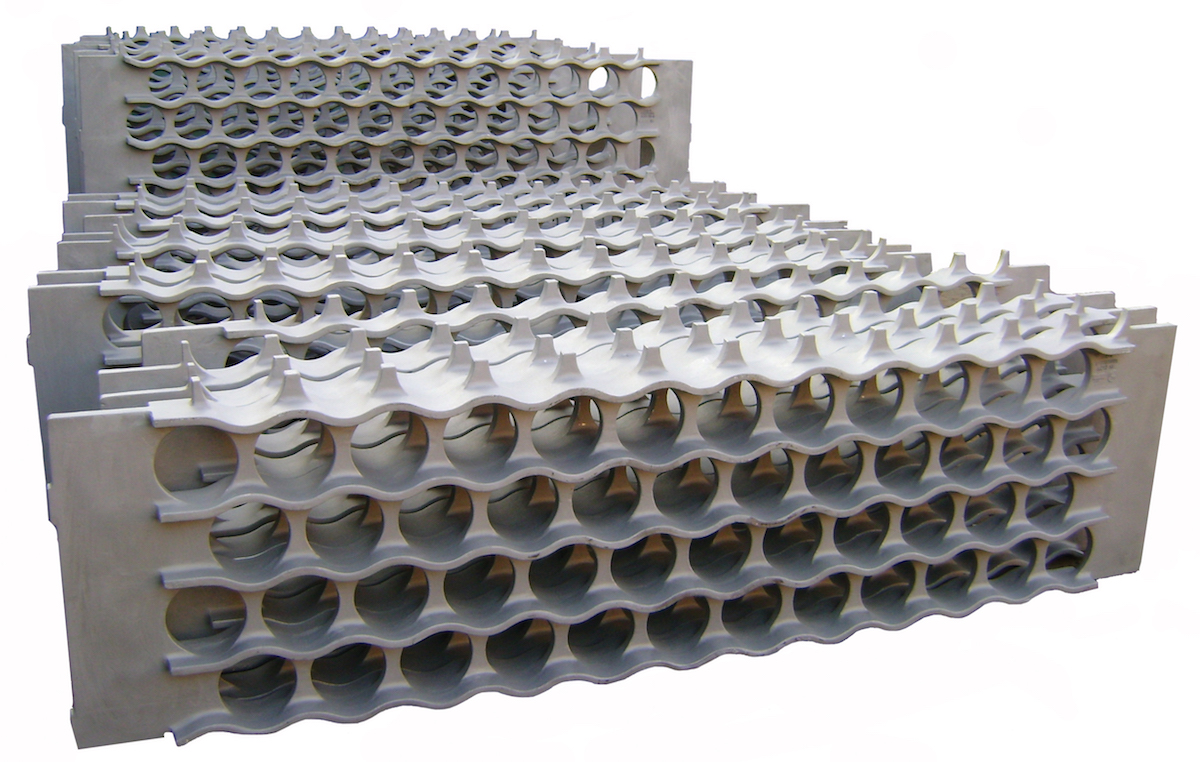

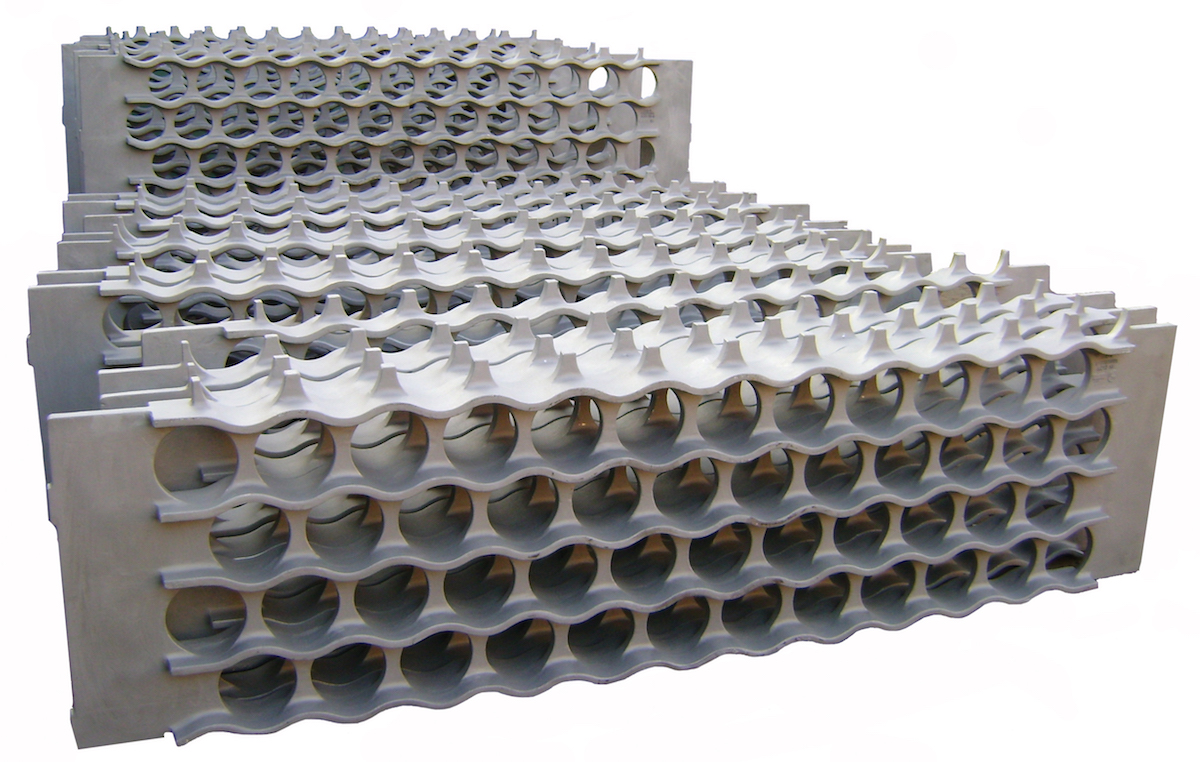

Cast Heat Treatment Work Carriers

Design, cast and deliver the highest quality cast work carriers.

Heat Treatment Furnace Parts

Internal furnace alloy cast and fabricated in our multiple US facilities.

Steel Production Support

Thermal resistant castings and fabrications for a multitude of industries.

Hyper Alloys

Rugged baskets, unique muffles, vacuum retorts, corrugated boxes, and radiant tubes hand crafted with exacting standards.

Contact Wirco

We are always here to answer your questions.

Committed to high quality products

Since 1969

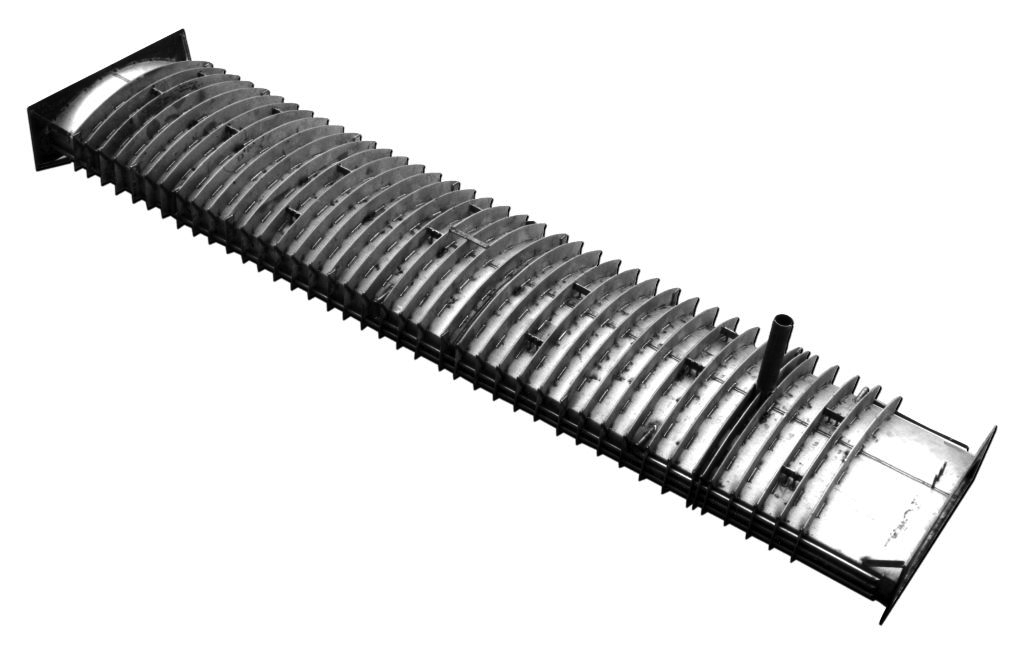

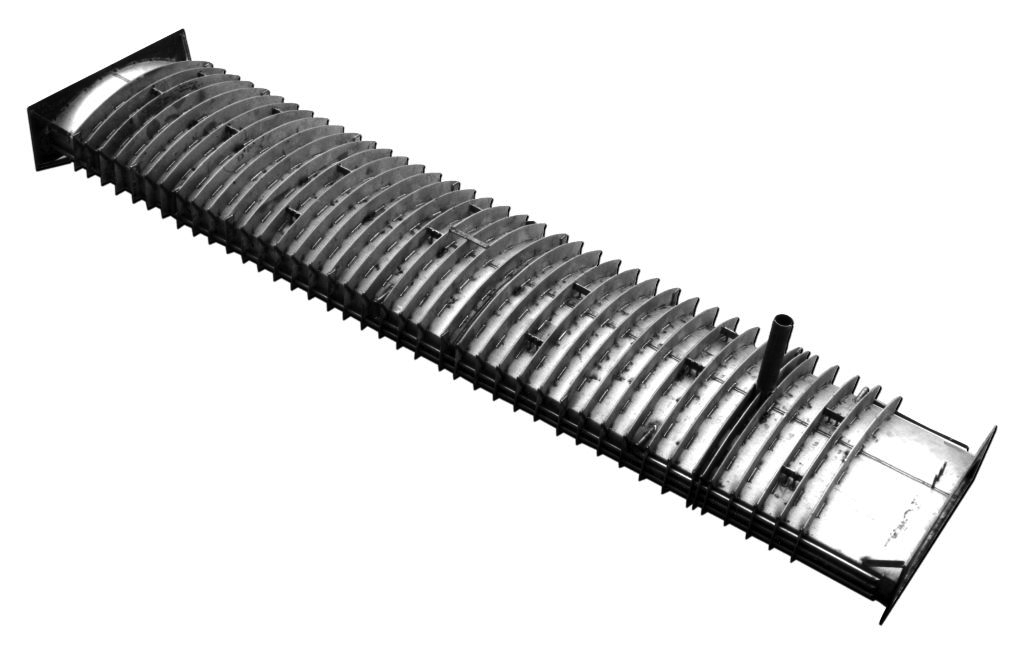

Hyper Alloys

handcrafted with exacting standards for over 50 years.

Wirco’s Hyper Alloys line of custom fabrications have been used in many facets of the thermal processing industry. Our rugged baskets, unique muffles, vacuum retorts, corrugated boxes, and radiant tubes offer a high-value and comprehensive inventory that heat treating managers and operators depend on.

FEATURED VIDEOS

Watch to Learn More About Wirco

FEATURED BLOGS

RECENT NEWS FROM WIRCO

Holiday Closure

Wirco, Inc. will be closed for the Holidays beginning on the afternoon of Friday, December 2 through January 1, 2024. We will resume regular...

Wirco is looking for Account Managers!

Come join Wirco's growing team. We are looking for an Account Manager to help with our growing sales. Please see the attached Job description and...

Wirco is Hiring!

CNC Machinists and Welders! Wirco is the top tier provider for stainless steel castings and fabrications for the Heat Treat and Steel Mill markets....

Designed and

Manufactured.

In The

USA