Cast Heat Treatment Work Carriers

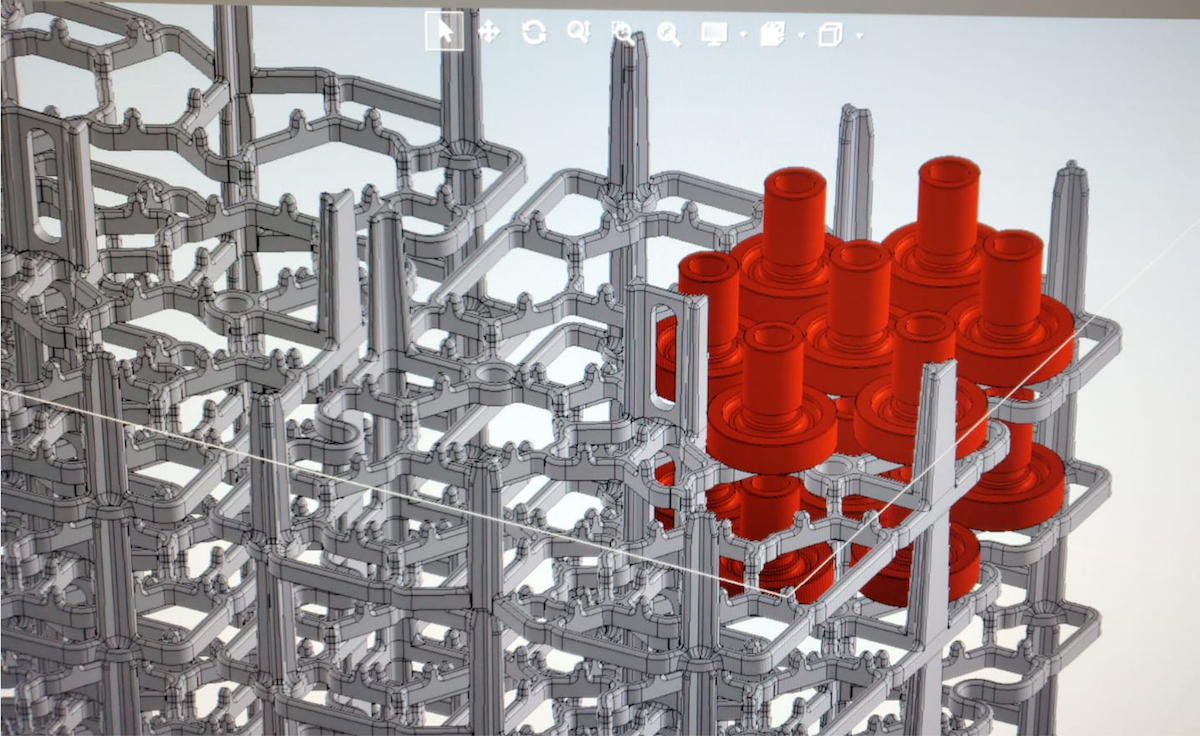

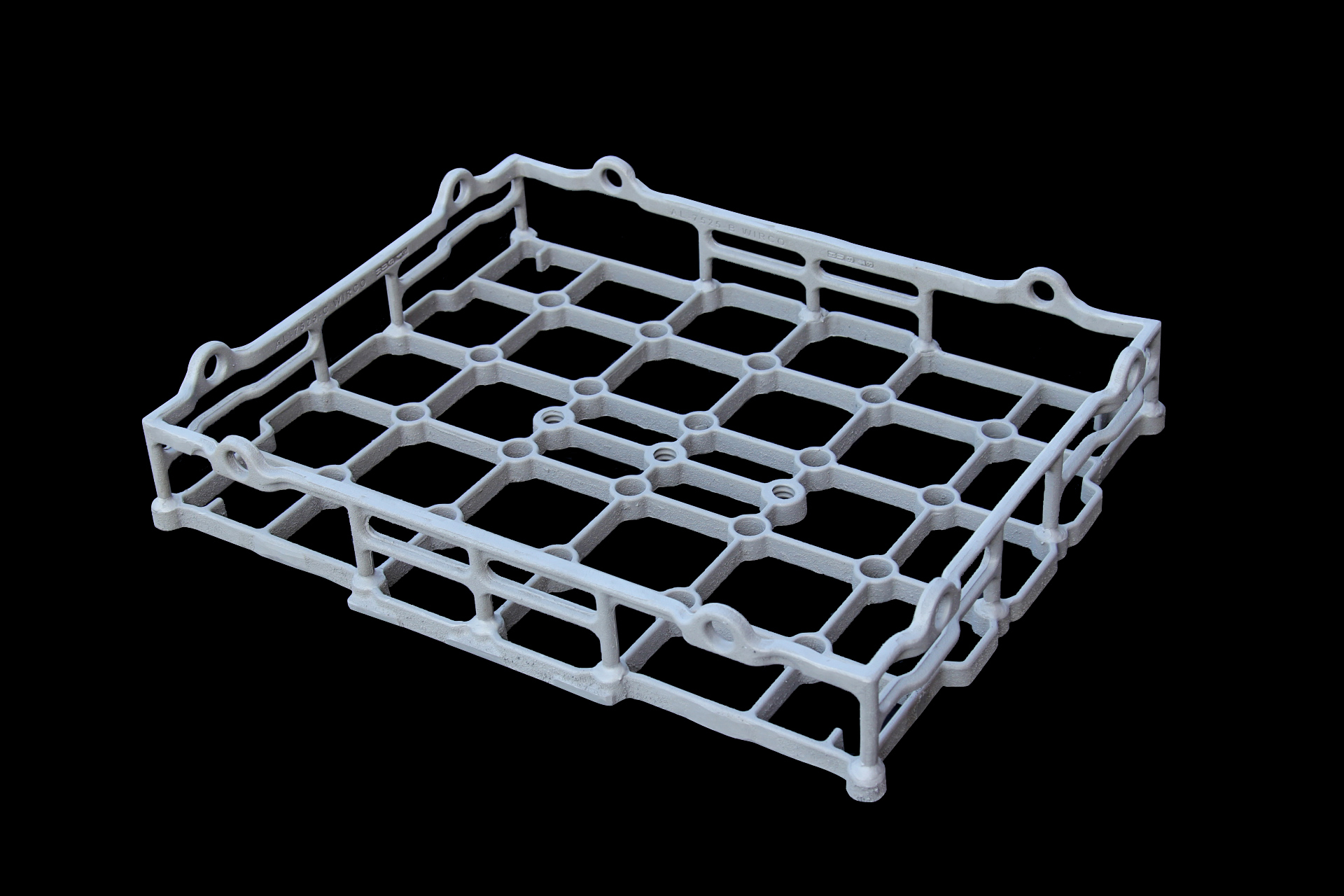

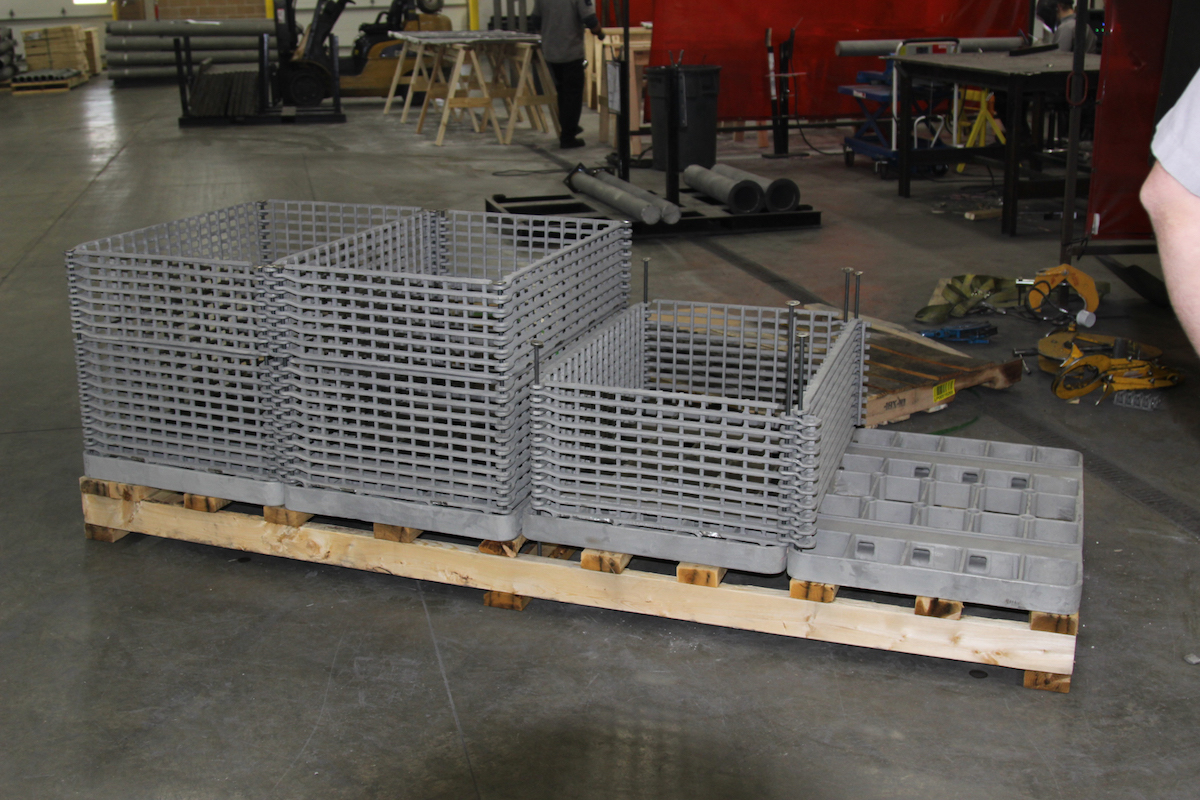

Wirco maintains a vast array of patterns heat treatment tooling patterns used in our Champaign, IL Foundry. We specialize in designing, casting and delivering the highest quality cast work carriers for over 50 years.

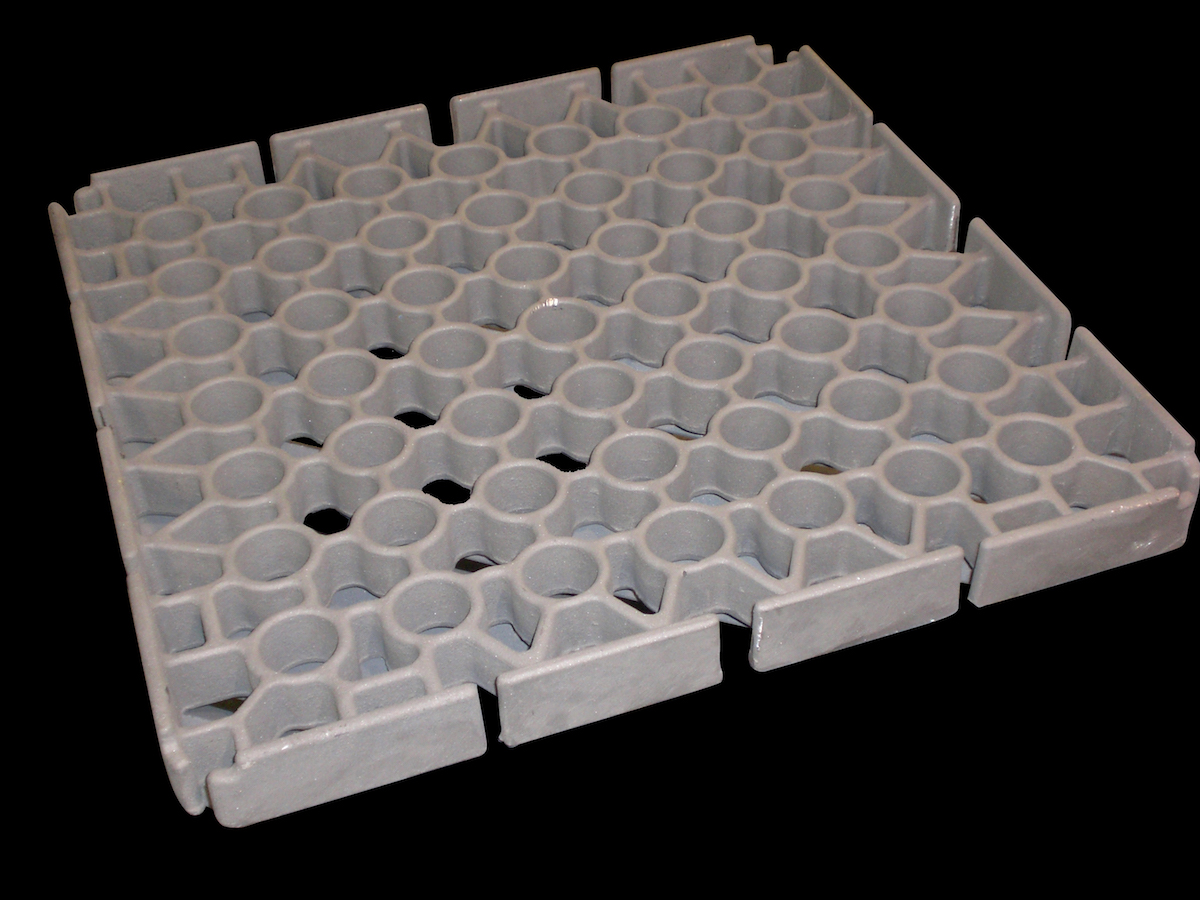

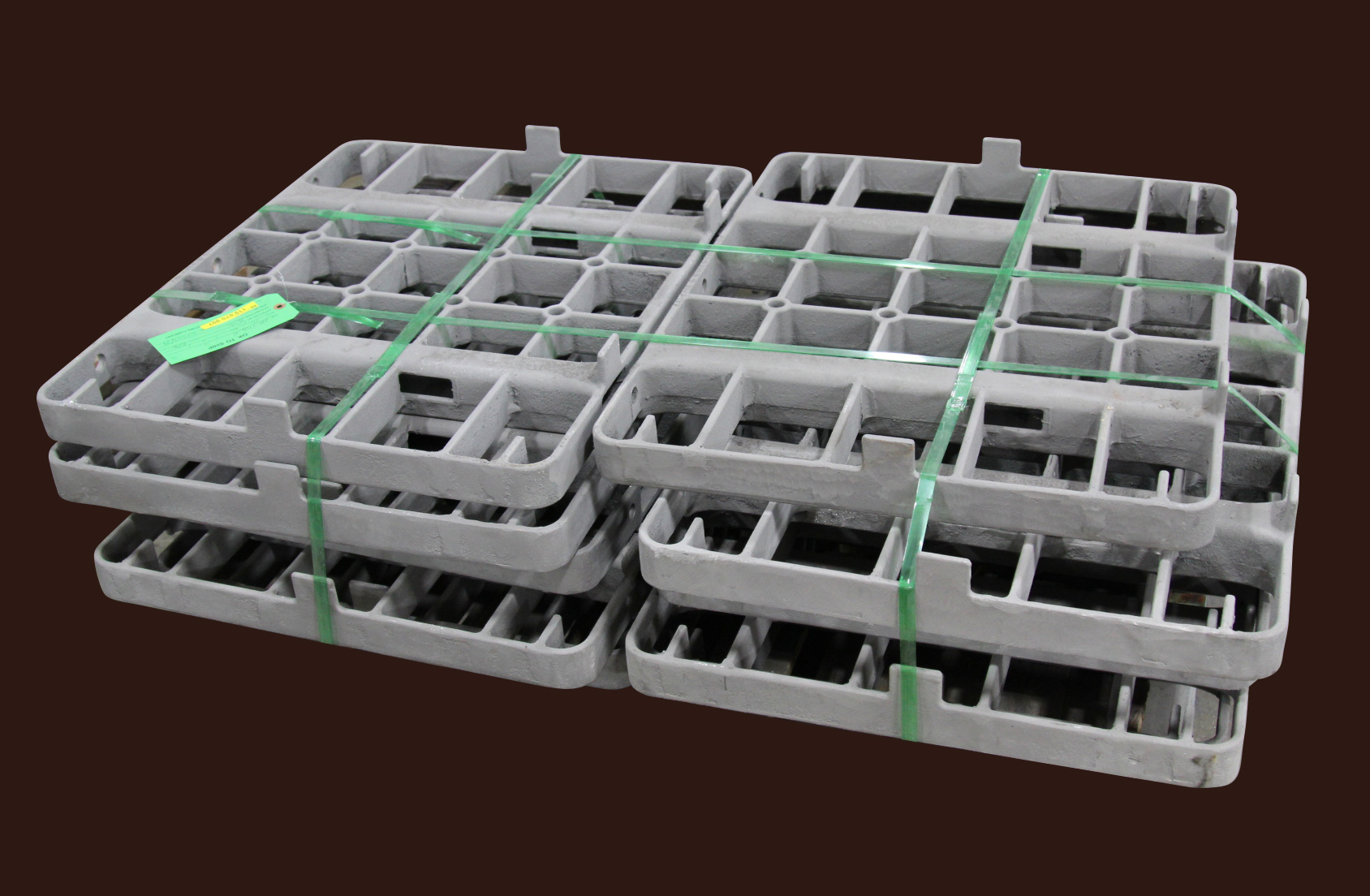

• Cast Furnace Trays

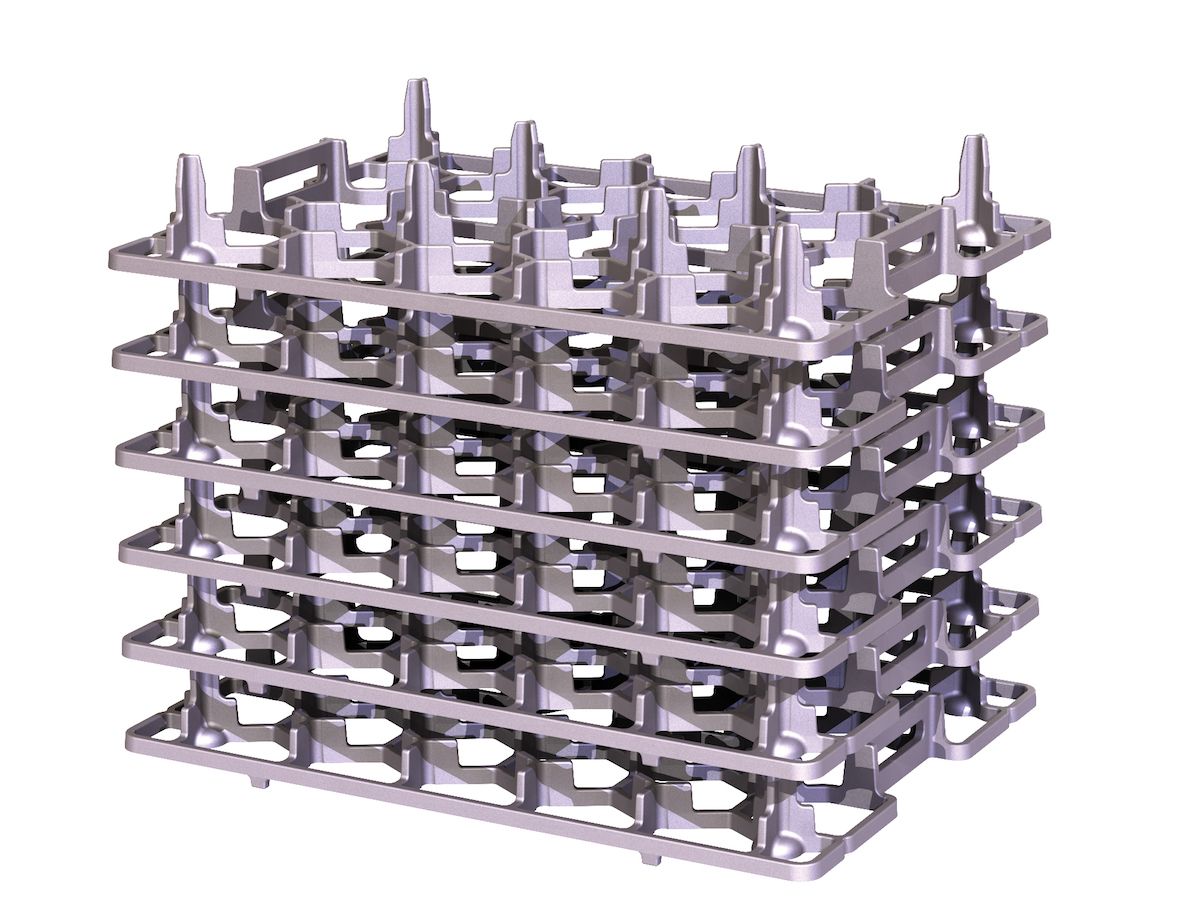

• Cast Gear Fixtures

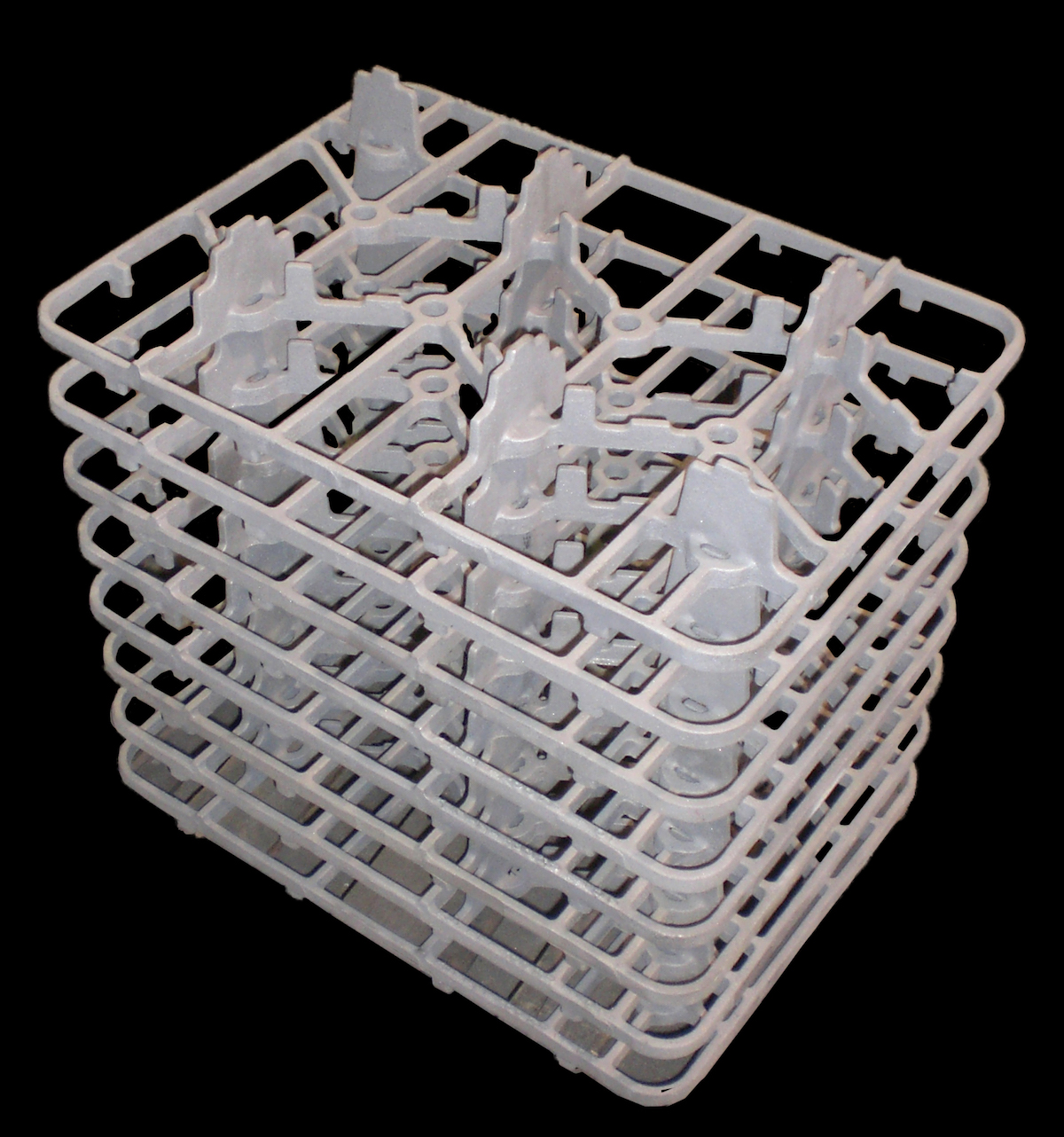

• Cast Baskets

• Cast Pit Furnace Tooling Systems

Innovative Approach

increasing overall efficiency

We give you long-term savings achieved by extended alloy life. Our team of highly skilled engineers and metallurgists provide innovative solutions that maximize alloy life and reduce operating costs. While it is great to fix a problem, we focus on the big picture by designing solutions that can simplify your supply chain, maximize parts per load, and increase your overall efficiency.

Featured Blogs

RECENT NEWS FROM WIRCO

Holiday Closure

Wirco, Inc. will be closed for the Holidays beginning on the afternoon of Friday, December 2 through January 1, 2024. We will resume regular business hours on Tuesday, January 2, 2024 at 7 AM. Wishing you and your team a very Merry Christmas & Happy New Year

Wirco is looking for Account Managers!

Come join Wirco's growing team. We are looking for an Account Manager to help with our growing sales. Please see the attached Job description and apply online under the careers tab Position: Account Manager, Wirco Incorporated Company: Wirco Incorporated is a third...

Wirco is Hiring!

CNC Machinists and Welders! Wirco is the top tier provider for stainless steel castings and fabrications for the Heat Treat and Steel Mill markets. With locations in Avilla, IN and Campaign, ILL, Wirco is growing and needs high quality and skilled people to join our...