Capabilities

Stainless Steel Fabrication

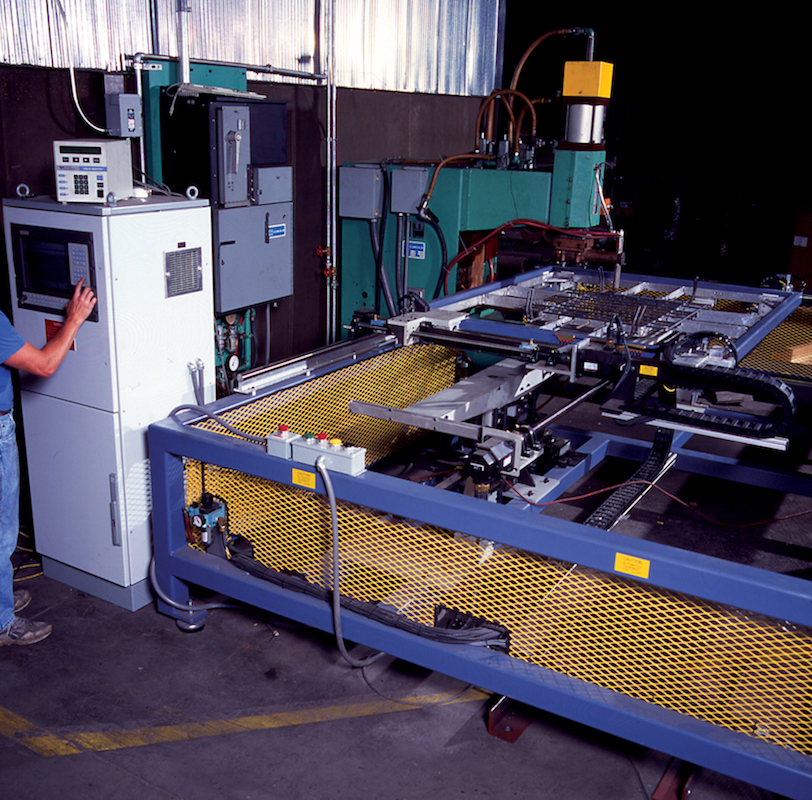

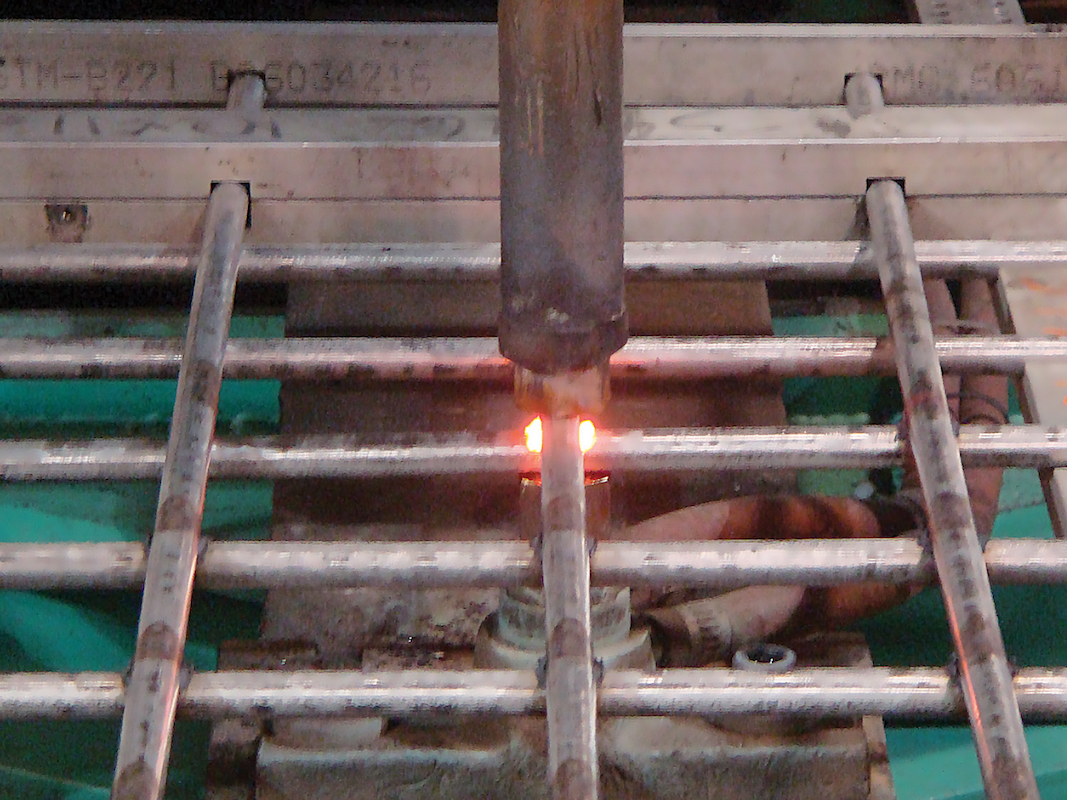

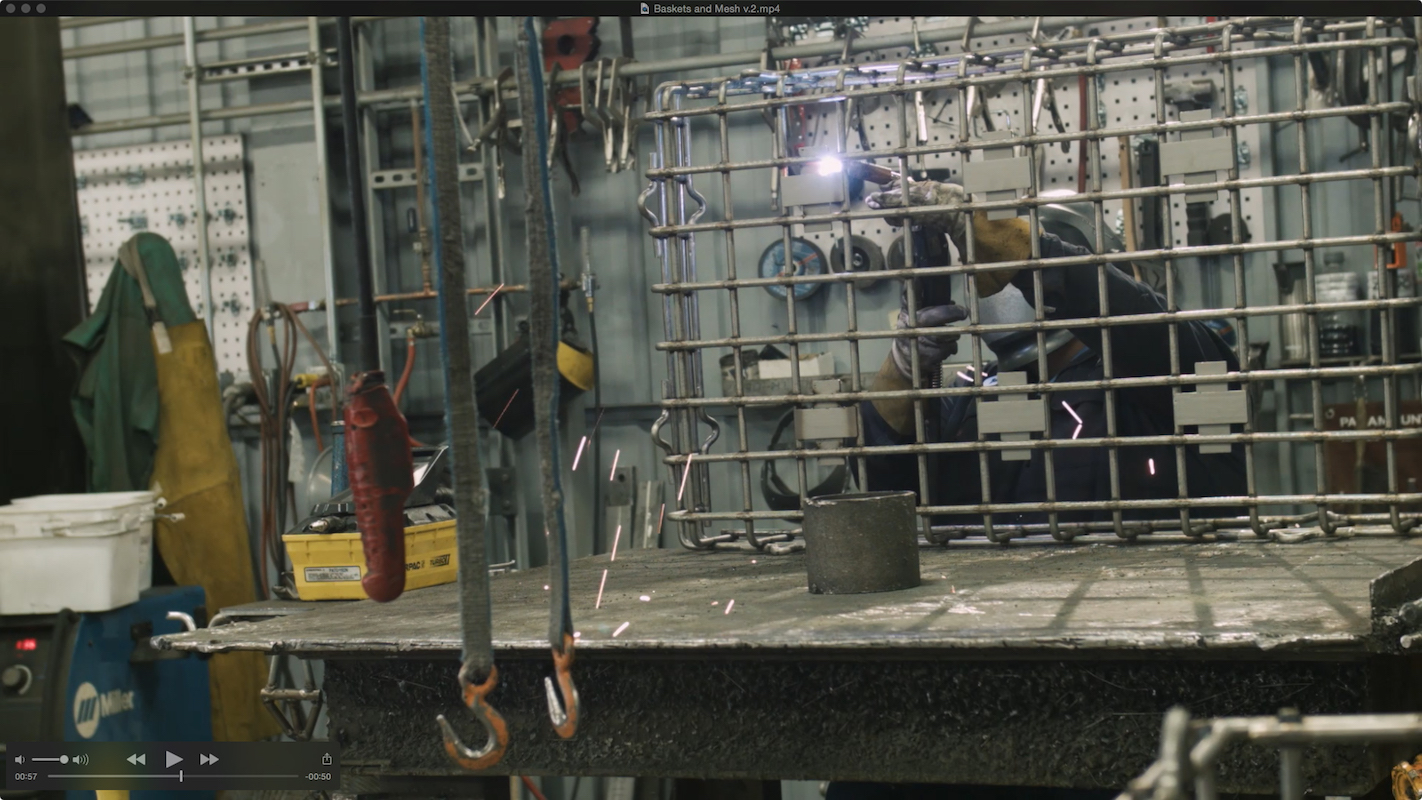

For over 50 years, Wirco has built and operated an industry leading stainless steel fabrication division now comprised of three manufacturing centers located in Avilla, Indiana. Robotic TIG, Automated Resistance Welding, Metal Forming, and a full complement of TIG, MIG, Stick, Plasma, and Autogenous welding systems complement our incredibly talented fabrication team. The Wirco Fabrication Division confidently partners with global clients for large volume heat treatment tooling projects, while also taking on highly complex small-lot fixturing systems and critical furnace maintenance alloy requirements. Our computer controlled welding equipment provides fast and consistent processing of our various types of baskets. This guarantees that every basket is precise and quality standards are achieved, thus offering you the best basket on the market. Weld strength is vital to the grid design used in our baskets. During the set-up of each new job, we check the tensile strength of the material and weld to guarantee proper weld fusion.

*Click to view larger image

*Click to view larger image

Fabricated Tube Welding

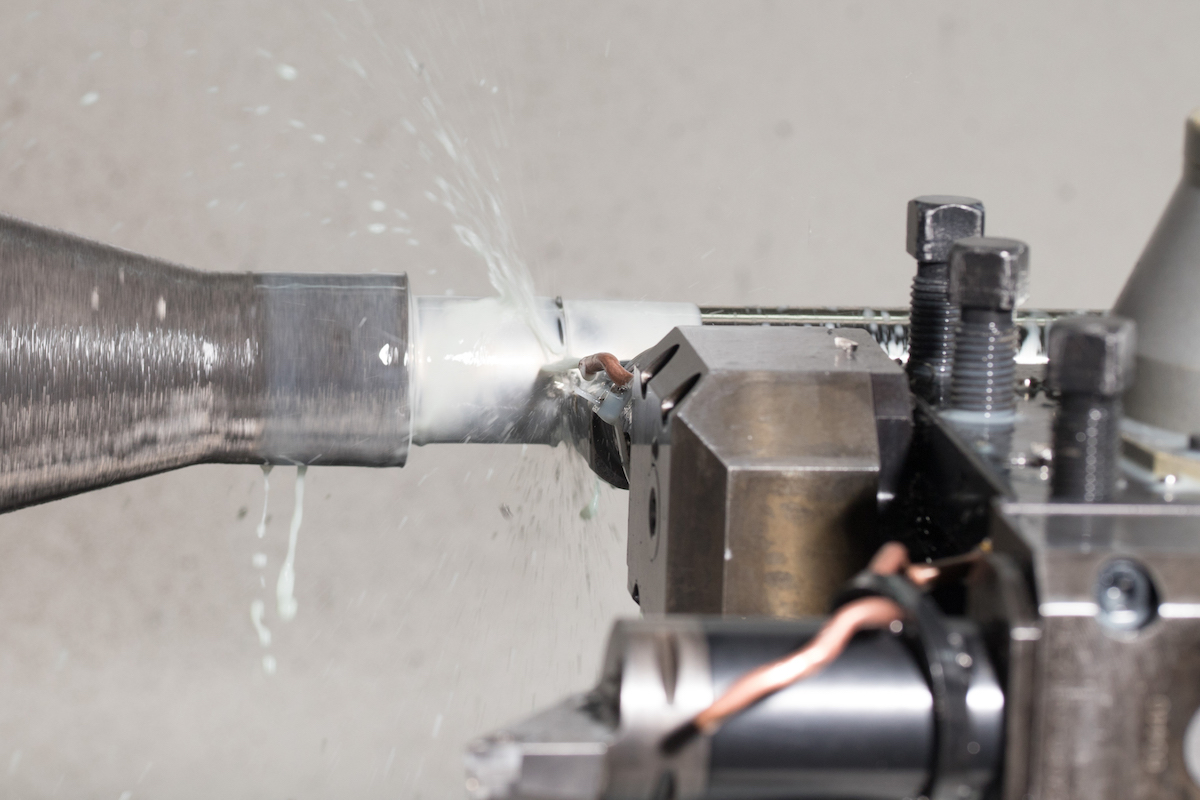

With the purchase of Hyper Alloys in 2017, Wirco now proudly offers leak-free stainless steel fabricated tubes produced on three unique tube-welding systems. Wirco fabricated tubes are formed to exact dimensions in either permanent dies or formed to our customers’ special dimensional requirements. Utilizing plasma welding, wire-fed plasma welding, and autogenous welding, our fabricated tube welding capabilities produce the finest seamed tubes ranging in size from 3” to 10” diameter and larger.

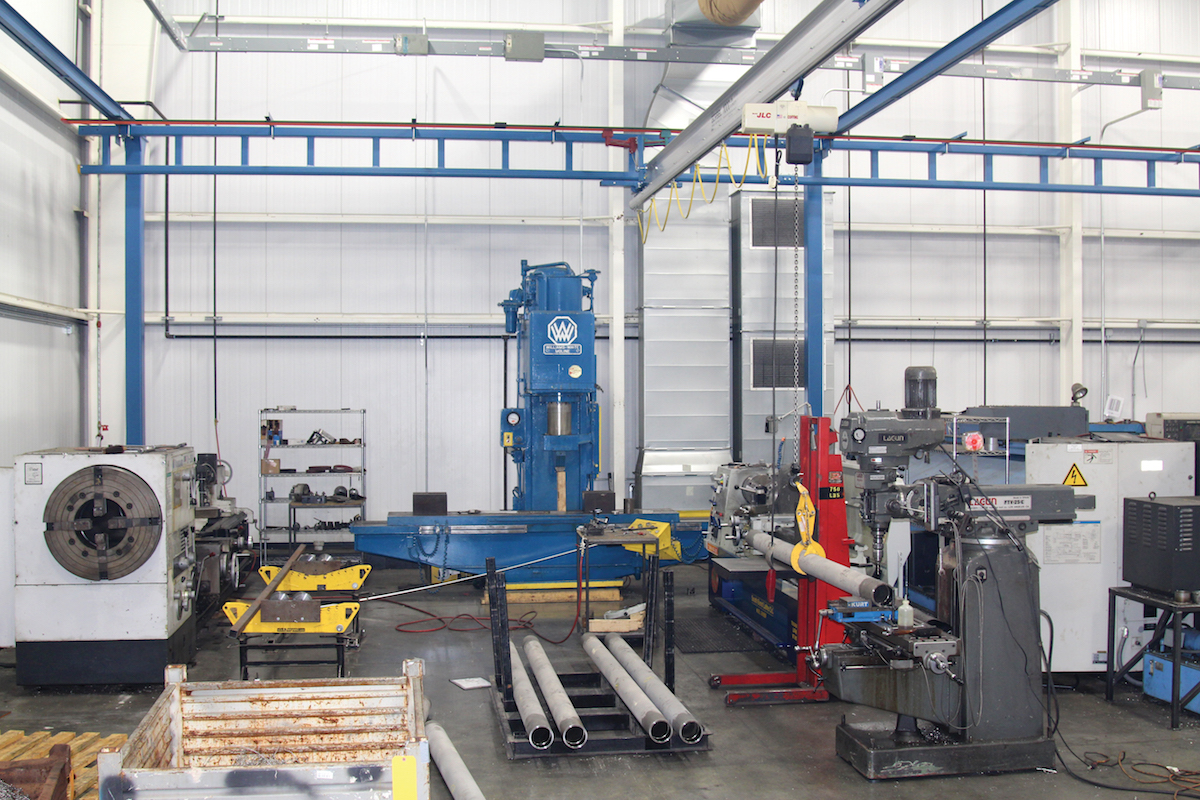

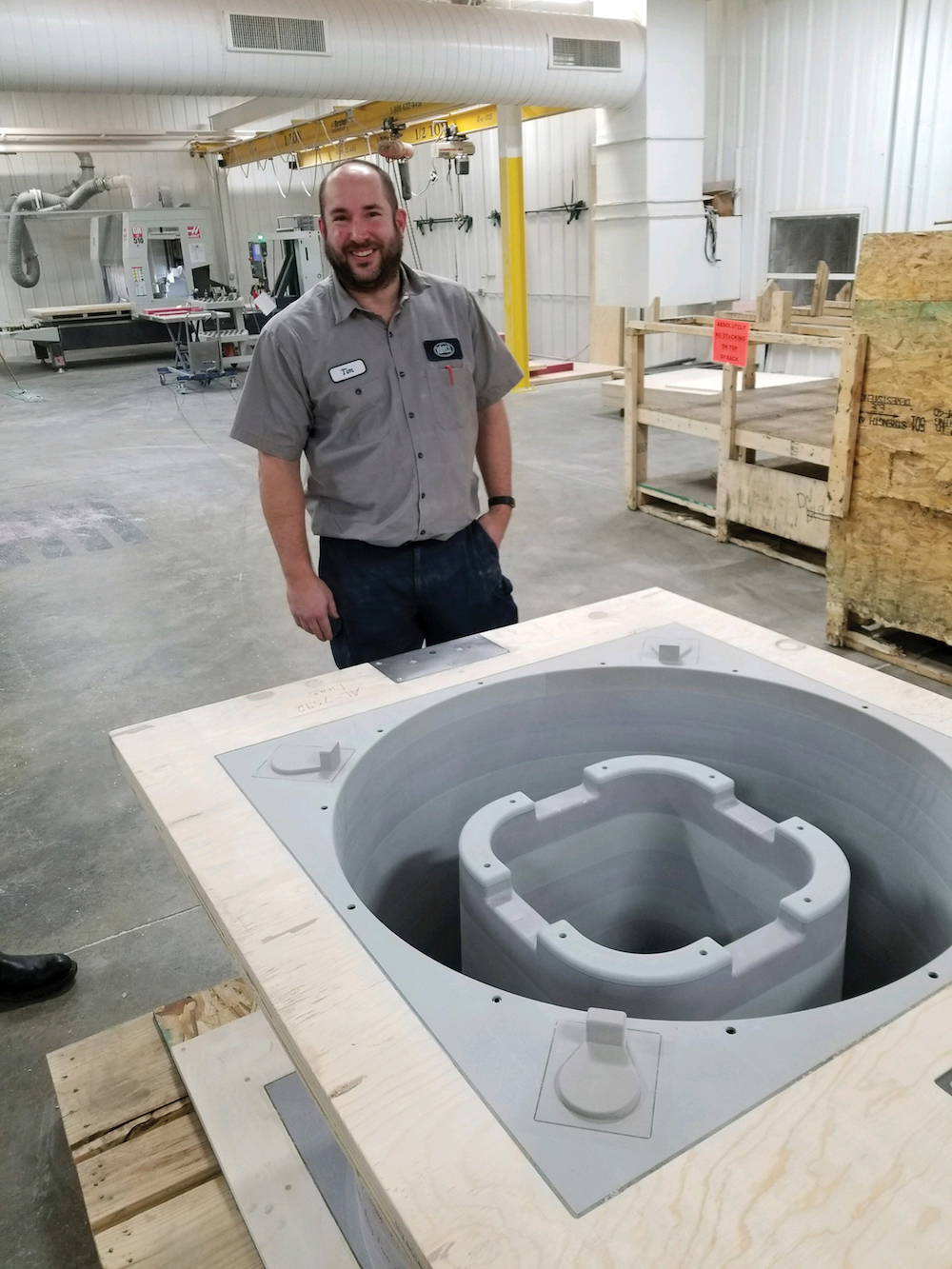

Machining Capabilities

Wirco is trusted to complete numerous fabrication and casting projects requiring highly accurate machining processes. With a strong commitment to vertical integration, Wirco funds and maintains a modern CNC Milling and Turning Center with a diverse assortment of equipment built to handle most of the machining requirements presented by our clients. Housed in a 30,000 sqft climate controlled space and staffed by a highly trained and skilled workforce, the Milling and Turning Center of Wirco Incorporated provides the high-quality parts our clients depend on.

*Click to view larger image

*Click to view larger image

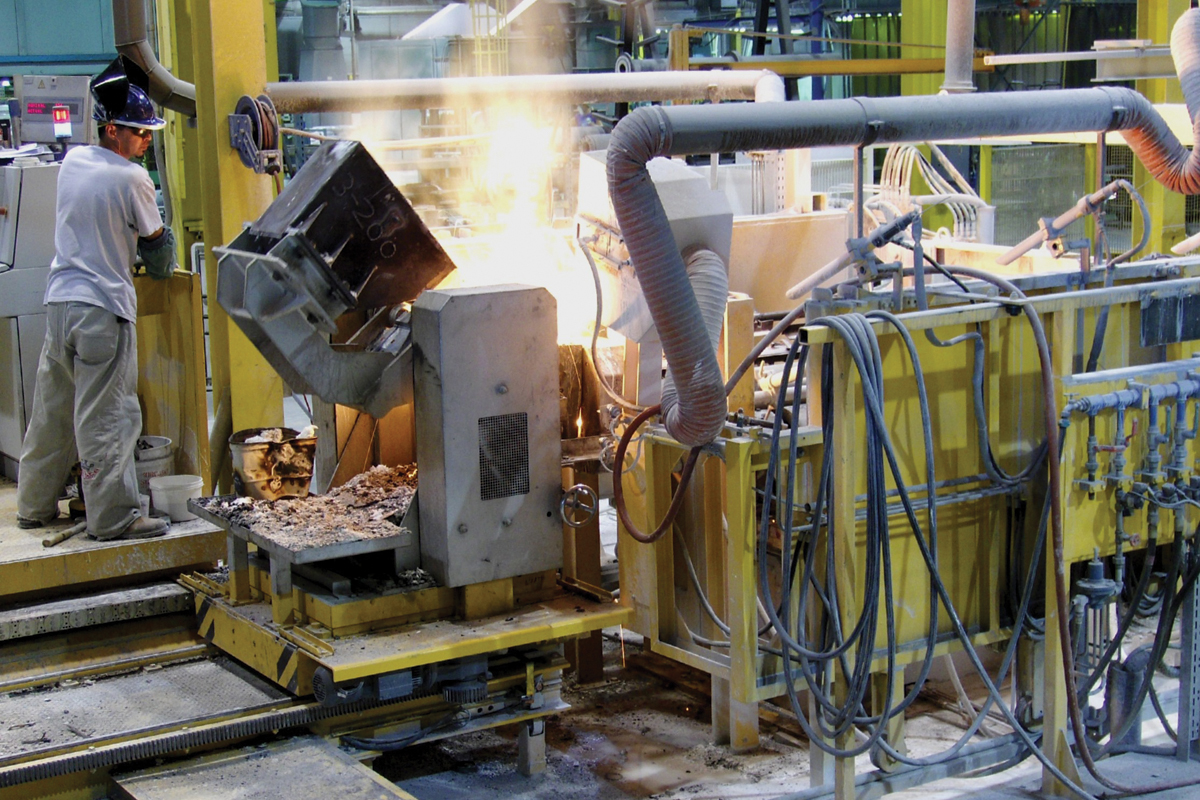

Casting Capabilities

Wirco’s technical expertise, experience, and modern facilities are at the forefront of the casting supply field. The Wirco foundry is a flexible, state of the art facility that can meet customer requirements through a full range of cast alloy products. By utilizing green sand molding, cold and hot box processes and permanent molds, Wirco’s diversification and flexibility are the keys to producing the highest quality castings.

Our facilities include both induction and arc furnaces allowing for the production of a wide variety of casting sizes, complexities, and weights.

Quality control is an important part of the Wirco production process. Gravity poured products incorporate ceramic gating, metal chills, and specialty sands to promote casting cleanliness and sound internal structure. X-ray examination is conducted on all new or re-designed castings by certified industrial radiographers in order to verify internal soundness.

Additionally, metal analysis for each furnace heat is certified by the spectrometer in our A2LA-accredited chemical testing laboratory. All castings are poured at the lowest possible temperature to promote finer grain structure, reduce internal shrinkage, and improve ductility. By using the optimal percentage of virgin material and teapot ladle pouring, Wirco is able to further ensure metal integrity.

Green Sand Mold Casting

Wirco Incorporated has a long history of providing green sand molded stainless steel castings for use in a variety of heat-resistant applications. Continuously producing castings for over 75 years in our modernized Champaign, Illinois foundry, the Wirco Foundry division (previously Alloy Engineering and Casting Company) is continually improving casting quality and manufacturing efficiencies to bring our customers the best value available. Green sand castings are produced using a mixture of high and low volume molding equipment. The expert staff of molders and foundry technicians at Wirco fully understand the challenges faced when casting heat-resistant stainless steels and work closely with our clients to deliver a highly engineered long lasting casting.

*Click to view larger image

*Click to view larger image

No-Bake [Airset] Mold Casting

In 2017 the Wirco Foundry Division installed an ultramodern Tinker Omega® No-Bake molding line to compliment the other molding techniques currently utilized at the Champaign Illinois foundry. This large-format line brings our clients improved surface finish with a high operating capacity which will increase casting performance and improve on-time deliveries. To keep costs low and quality high, the Tinker line’s innovative on the fly sand mixing capabilities, and the ability to reclaim fired sand, bring unparalleled casting efficiencies.

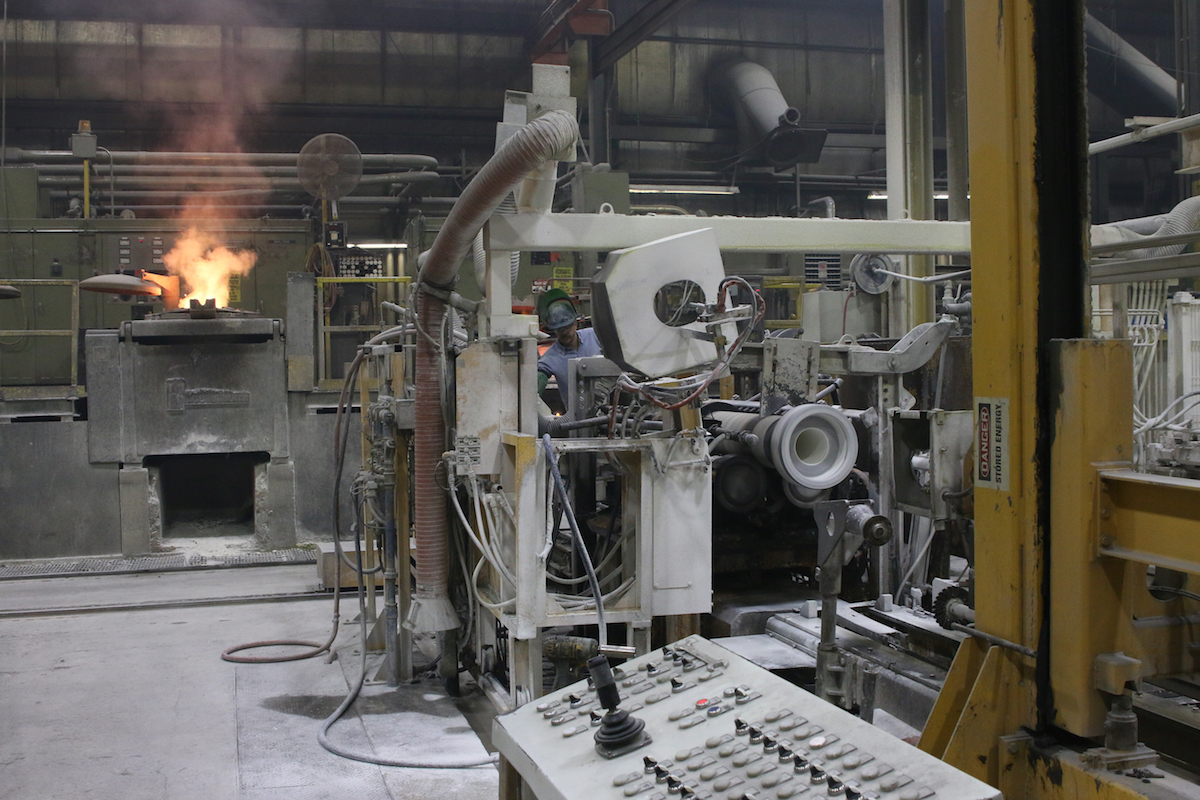

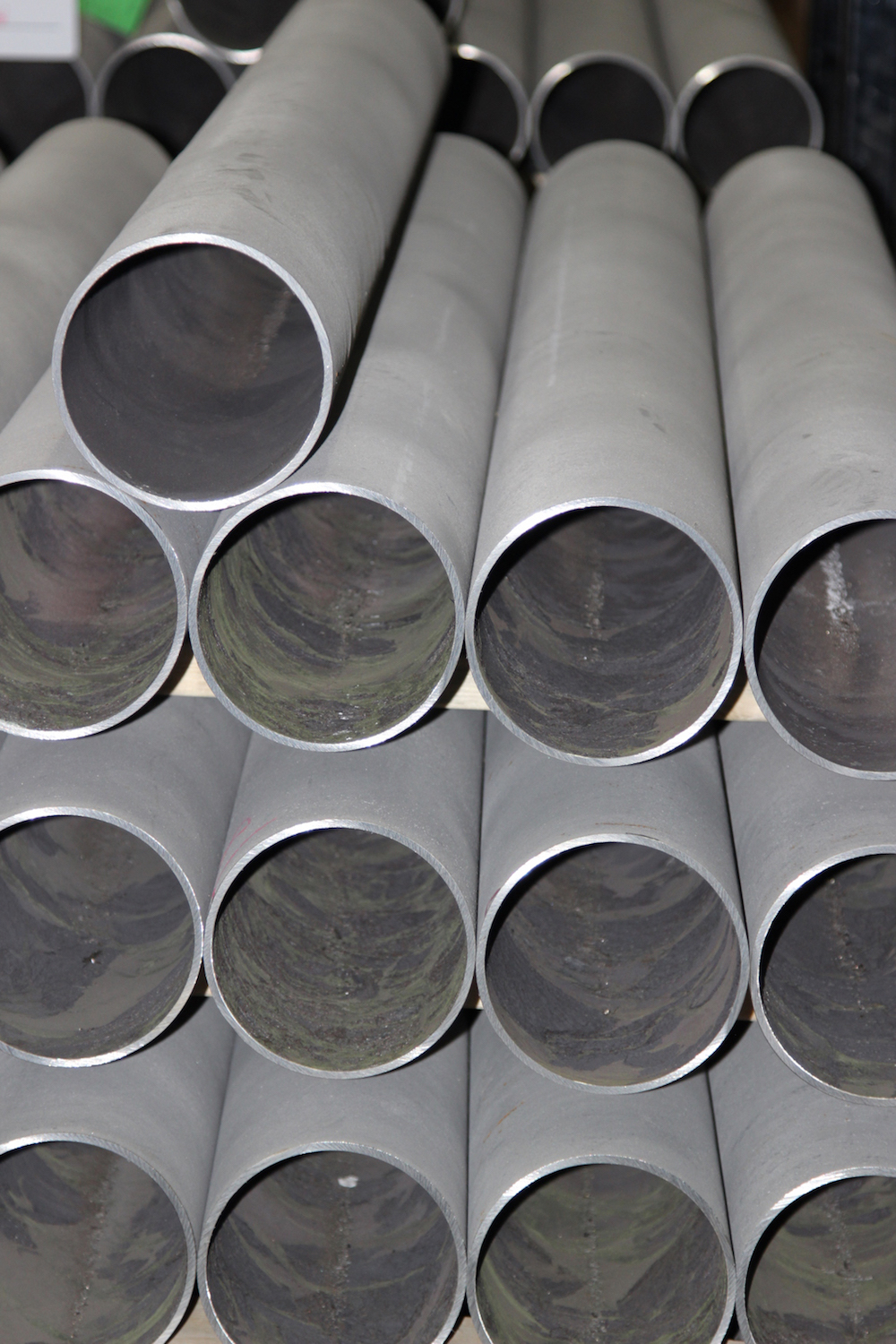

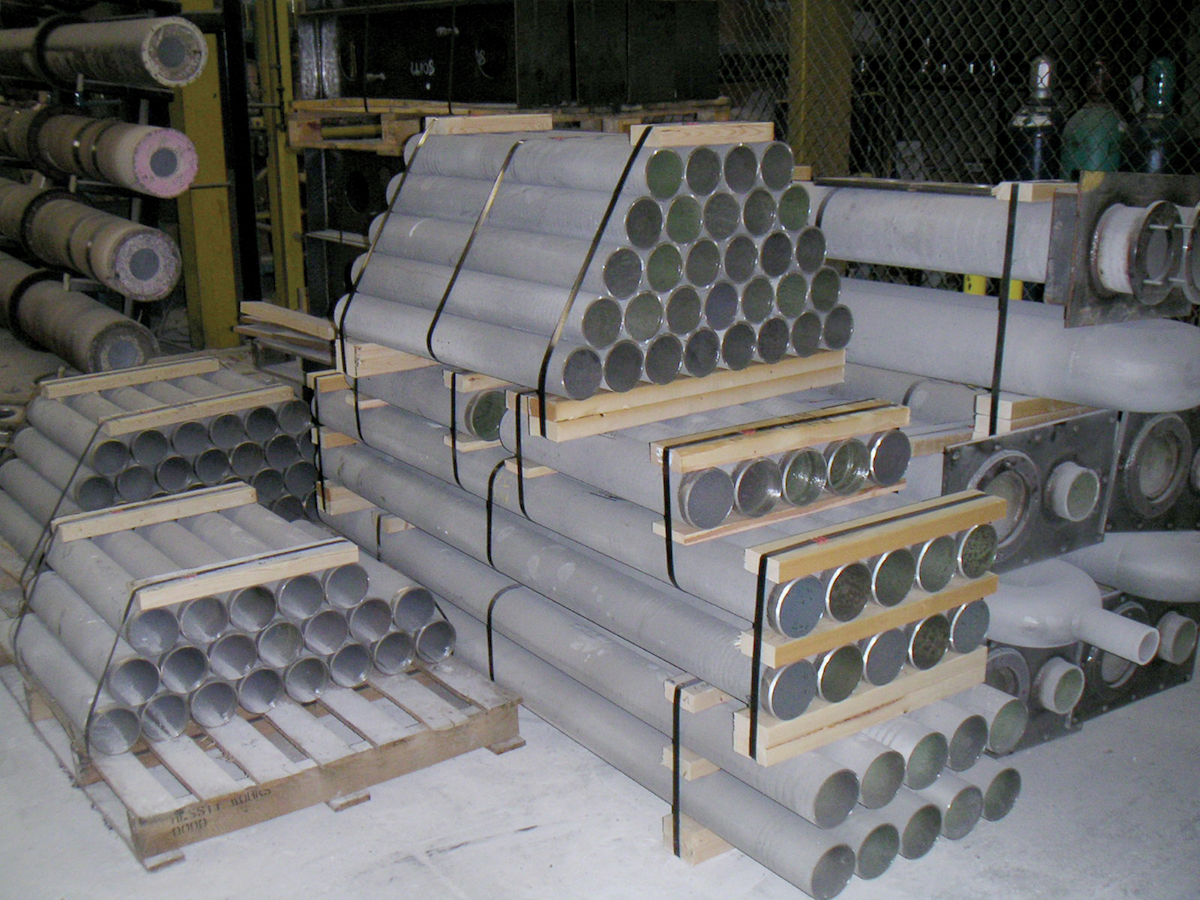

Centrifugal Tube Casting

Wirco produces centrifugally cast heat-resistant alloy tubes in precision machined permanent molds for outstanding dimensional accuracy and leak-free operation. Utilizing a fully automated DUKER® centrifugal casting system, Wirco tubes are unmatched for surface finish quality and assembled into some of the most demanding high-temperature processes our clients possess. Wirco cast tubes are commonly found in heat treatment furnaces operating in temperatures in excess of 2100F. You can also find Wirco tubes built into high-temperature roller conveyors, electric element protection cans, and numerous other high-temperature applications. All Wirco cast tubes undergo rigorous quality examinations so Wirco customers can be guaranteed the highest service life with industry-leading value.

*Click to view larger image

Our commitment to quality is evident in the monitoring and pouring of centrifugally cast tubes both before and after pouring. Melt heats are checked through spectrographic analysis in our A2LA Certified lab. Pouring temperature is monitored using a submersible pyrometer. Dye penetrate, borescope, and pressure testing are used as required to monitor the integrity of the finished tube, return bends, elbows, and fabrication.

Metal Melting Equipment

*Click to view larger image

Electric Arc and Induction Melting

The foundry division of Wirco Incorporated has a variety of modern induction and arc melting furnaces. Wirco operates six Inductotherm® induction melting systems ranging in size from 600 to 2000 lbs. Large volume melt operations are conducted in our 5000 and 2000 lbs. electric arc furnaces. Wirco proudly has a combined melt capacity of 16,000 lbs. per hour of simultaneous melt operation. With so many furnaces available, Wirco’s heat treat clients have come to rely on Wirco’s industry-leading melt capacity and the delivery performance of duplicate melting systems under one roof.

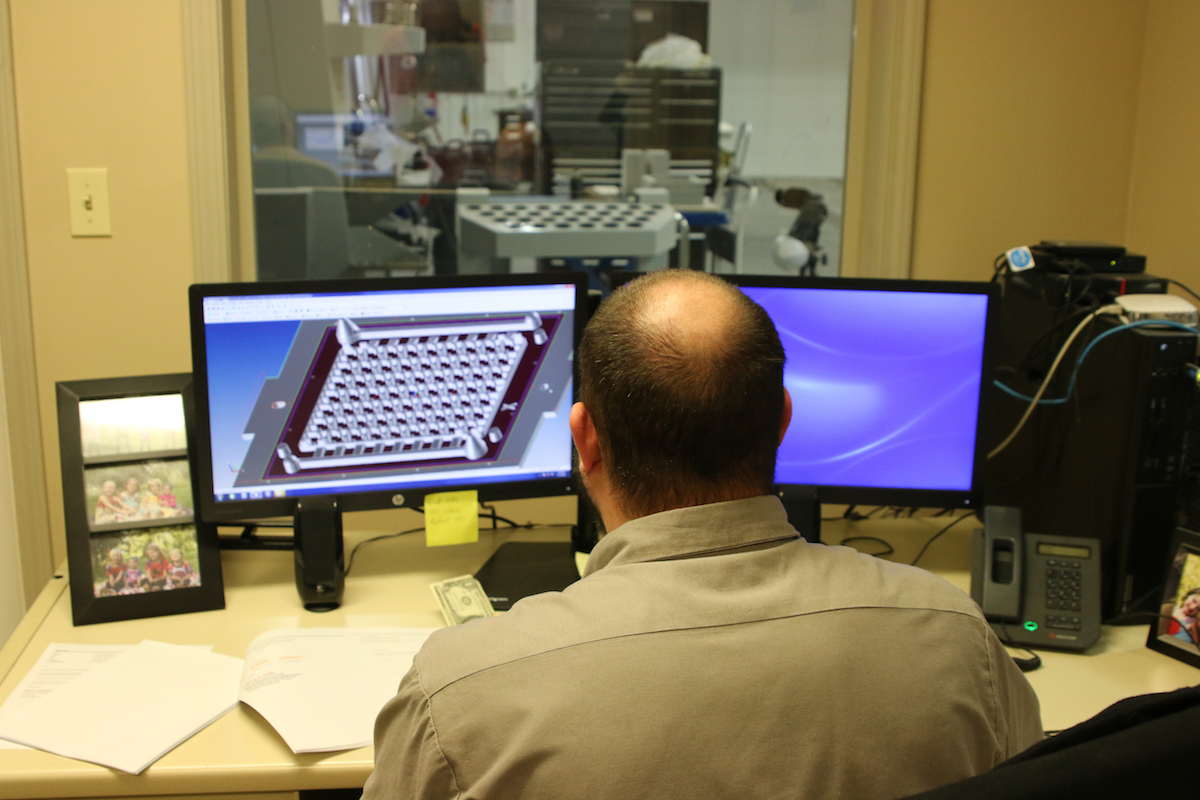

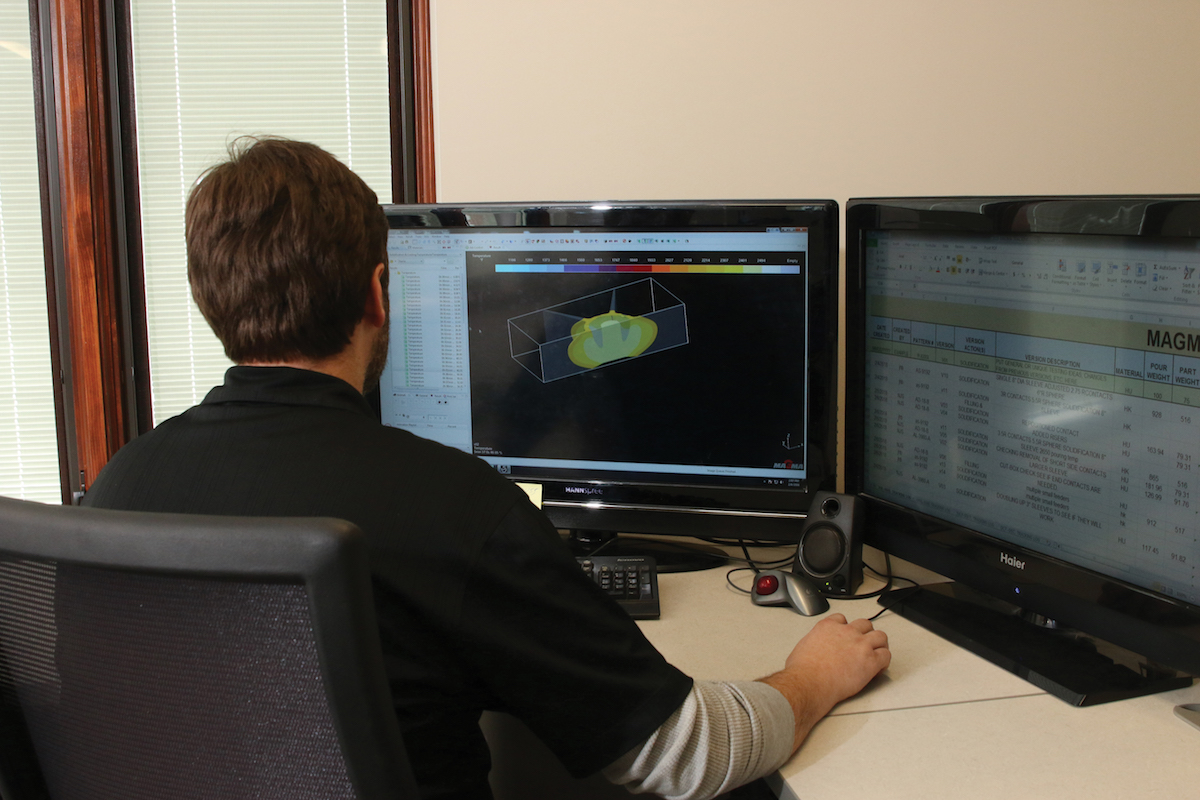

In-house Pattern Construction

Patterns are a critical component of the casting process, which is why Wirco has always staffed and maintained an in-house pattern department. Pattern construction starts with Wirco’s process engineering group where skilled engineers finalize solid model drawings of the pattern. The design will then be rigorously tested using Magma Flow simulation software to determine the best pattern configuration needed to achieve a solid casting. The approved model is transferred to the Avilla CNC pattern shop where it is converted to machining code using Surfcam 3D Milling Software. Pattern machining is accomplished using two gantry style CNC mills in addition to two standard CNC mills.

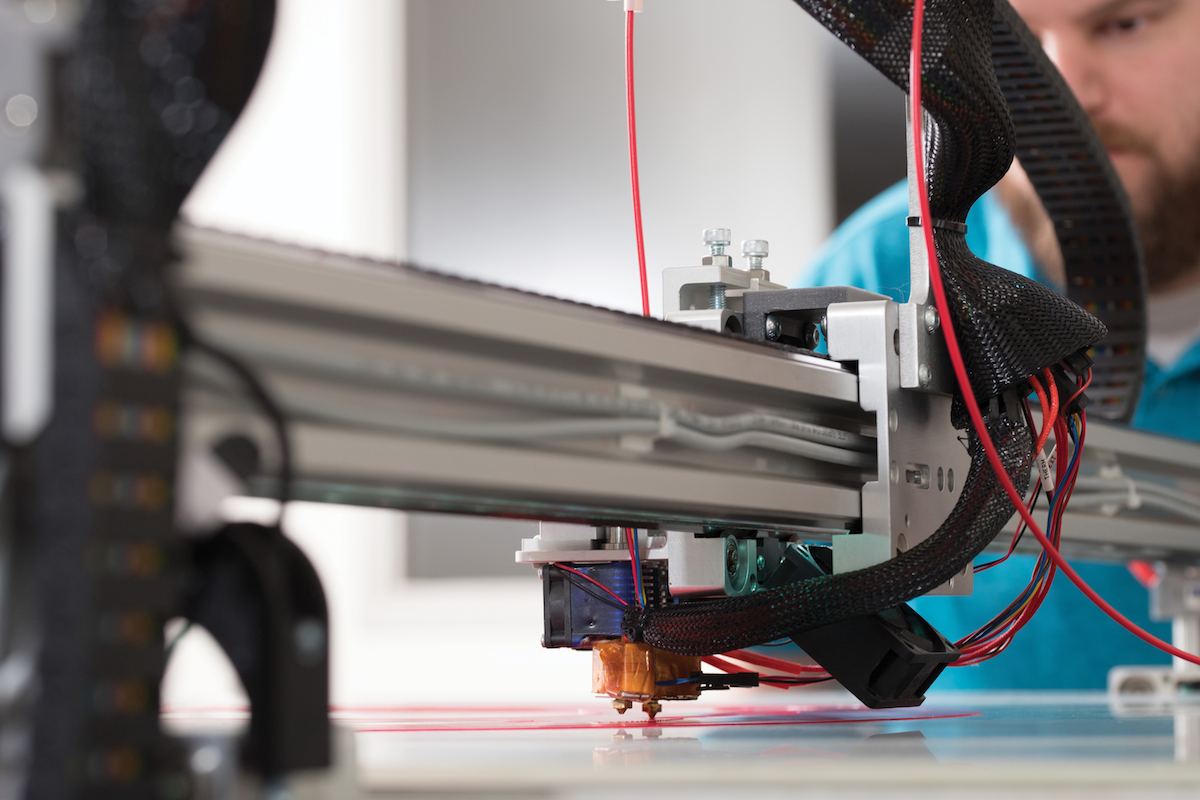

*Click to view larger image

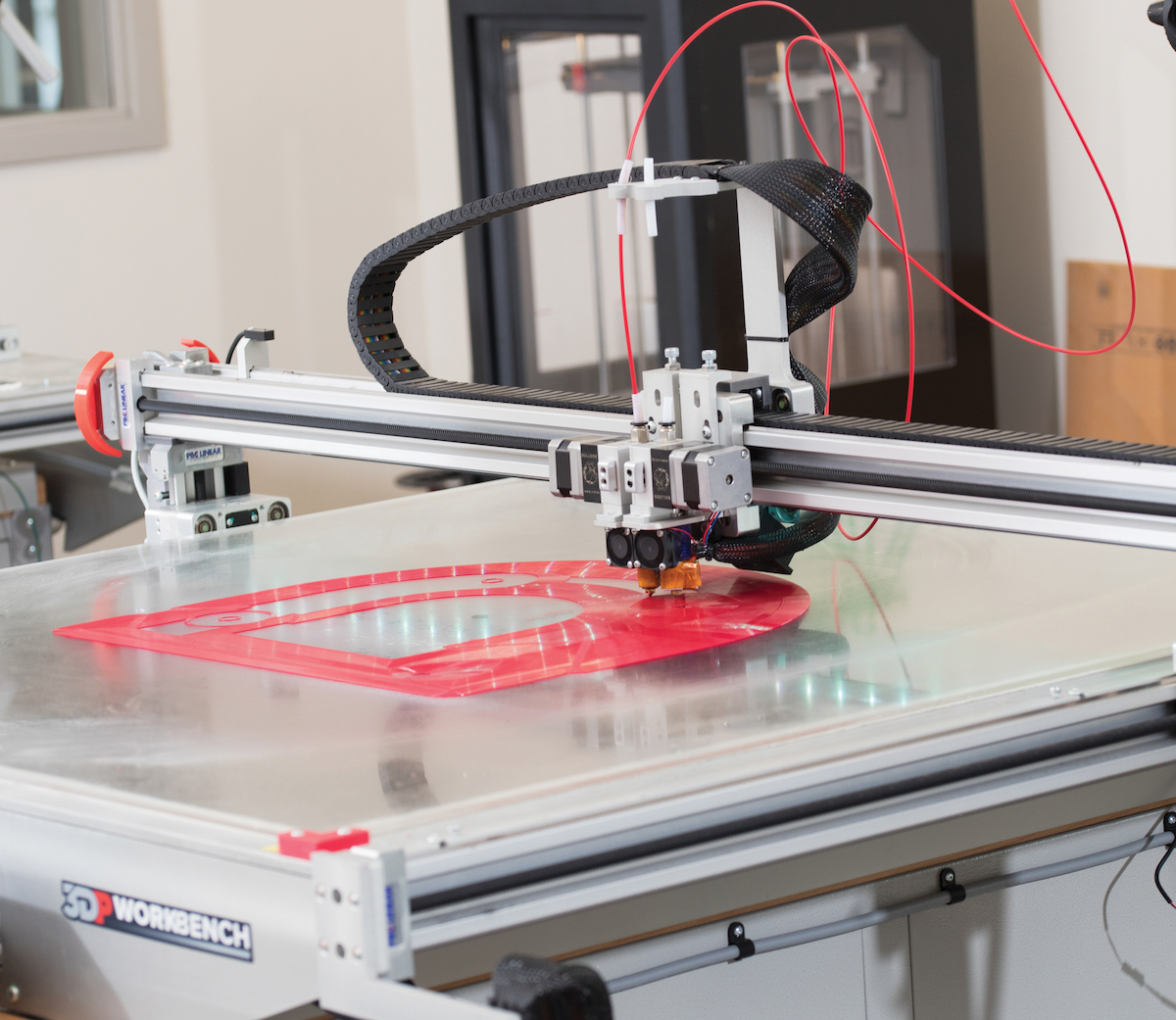

Wirco patterns are primarily cut from high-density polyurethane Ren Board, but occasionally patterns will also be constructed from wood, aluminum, and steel. Two large-format 3-D printers are also employed for rapid prototyping requests from Wirco customers. Final pattern prepping and repair operations are conducted by skilled craftsmen at the Wirco foundry in a newly constructed pattern staging area. Completed patterns are stored in a secure and isolated pattern storage warehouse. The recently constructed pattern warehouse offers a climate-controlled environment for long-term pattern life and full fire suppression with dedicated racking for pattern safety.

*Click to view larger image

Engineering Capabilities

Wirco’s industry-leading engineering department offers highly skilled design and process engineers with a dedicated focus to take your project from initial design creation through project completion. Major manufacturing clients utilize our engineering team in a variety of industries to provide the best solution and service life for your cast and fabricated heat-resistant alloy tooling and furnace part applications. The engineers at Wirco have successfully completed hundreds of new design projects utilizing 3D Solid Works ® along with F.E.A (Finite Element Analysis) for custom designed tooling bringing tremendous value and service life for even the most challenging requirements. Additionally, our engineering team has helped to redesign existing customer tooling to increase service life, maximize load efficiencies, and improve heat treatment quality.

Our ability to design products and build patterns in-house provides our customers with reduced costs, shorter lead times, top quality, and reduced errors on new projects.